Every business, whether big or small, starts with a great idea; it must be followed with the determination to succeed and sustained with hard work. From then on, everything else (well, almost) comes easy.

For the Arcangel couple, Engr. Antonio and wife, Doris, former OFWs based in Toronto, Canada, the decision to establish a business in the Philippines was prompted by a choice between selling their 20-hectare idle land in Ilocos Norte or to continue cultivating it. Portions of their land, although planted to rice and tobacco, were mostly idle and unproductive. Once they made up their choice, there was no turning back. With their decision to keep the land came the search for the great idea: what crop to plant? They did not have to look far.

Around this time, Engr. Antonio had heard and read so much about sweet sorghum and its potentials. The enactment into law of Republic Act 9367, otherwise known as the Biofuels Act of 2006 in January 2007, provided fresh incentive for the government to kick into high gear its efforts to develop, produce, and distribute high-quality, reasonably-priced and environment-friendly alternative fuels. One crop that was being looked into for its potential as feedstock for bio-ethanol production was sweet sorghum.

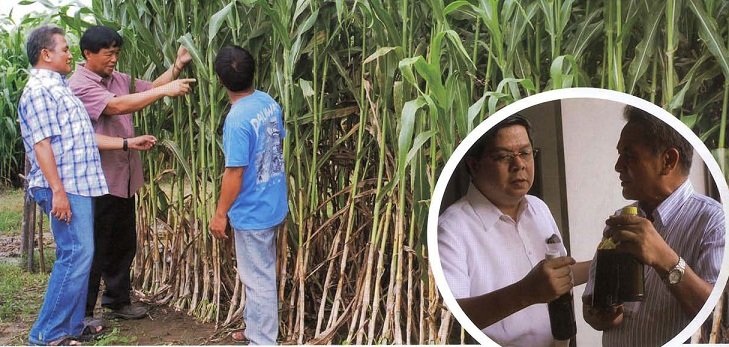

It also helped a lot that the Arcangel farm was just near the Mariano Marcos State University (MMSU), which through a funding support from BAR, was then conducting sweet sorghum technology demonstration and production in field trials at the MMSU campus. The sweet sorghum varieties being tested for adaptability came from the International Crops Research Institute for the Semi-Arid Tropics (ICRISAT) a research organization based in India that first introduced the crop in 2005.

With their interest caught, the Arcangel couple sought the assistance of Dr. Heraldo L. Layaoen, MMSU’s vice president for administration, planning and external linkages who happens to also be the national program coordinator for the sweet sorghum project, to help them establish a sweet sorghum plantation.

Sweet sorghum is not just about the fuel

Although sweet sorghum is being intensively promoted as an excellent source of biofuel, its use for fuel production needs bigger investments both in hectarage of sweet sorghum plantation that needs to be established and in the required distilleries that will process them into ethanol. While the realization of extensive biofuel production is yet to be realized, farmers must make the most out of the acreage of sweet sorghum they have planted. Happily, aside from fuel, sweet sorghum is also an important source of food, feed, and fertilizer. That’s why it is appropriately dubbed as the “F4 crop”.

Due to the nonexistence of local distilleries for sweet sorghum to produce the ethanol, MMSU has supported activities for developing other products from sweet sorghum. This is complemented by R&D initiatives from other institutions such as the Pampanga Agricultural Colleges (PAC), Isabela State University (ISU), and the Department of Science and Technology (DOST).

Sweet sorghum produces two important products: the grains which bear starch and the stalk which holds sugar-rich juice. Developed from the grains by researchers are sweet sorghum pop and flour which can be processed into bread and pastries while from the stalk’s juice come products like basi or wine, vinegar and the syrup which is promoted as a healthy alternative to sugar and sugarcane-based syrup.

Establishing the BAPAMIN Farmers’ Cooperative

Realizing the potential of sweet sorghum food products as an agribusiness enterprise as well as a viable livelihood for farmers, MMSU not only developed sweet sorghum products but also disseminated the production technologies to sweet sorghum farmers. The farmers started processing sweet sorghum products at the micro level but, in time, reached the attention of other interested private individuals like the Arcangels.

“These farmers, although they have tried adopting the technologies we taught them, they had no experience in marketing their products. Furthermore, there was this lack of a marketing arm to sustain the industry. It was at this point that the Arcangel couple came into the picture. They were receptive to new technologies so we encouraged them to invest in the production and the utilization of sweet sorghum as well,” revealed Dr. Layaoen.

But instead of merely going into sweet sorghum production as a family enterprise, the couple was also convinced by Dr. Layaoen to organize a farmers’ cooperative, now known as the BAPAMIN Farmers’ Cooperative, which engaged in the actual production of grain and juice from sweet sorghum, and which also went into the marketing of the produce.

To make sure that there would be ample supplies of sweet sorghum to process, the couple had to encourage more farmers to plant the crop. They also had to look for ways to ease the entry of other farmers into sweet sorghum production. One of the first problems that had to be solved was the milling of sweet sorghum. At that time, there was only one stationary mill for sweet sorghum and it was situated in Bungon, Batac, Ilocos Norte . “Transporting these stalks would be expensive so we designed a mobile mill which the Arcangel couple fabricated with their own money. The advantage of this mobile mill is that it can be taken directly to the field and extract the juice right away, thereby simplifying the whole process of processing and transporting the juice,” explained Dr. Layaoen.

To further ensure the continuous production of sweet sorghum, the Arcangel couple tapped the Bungon Seed Producers Multipurpose Cooperative, a group of farmers that plant and grow sweet sorghum for seed production, to supply them the planting materials for expansion.

Marketing food products from sweet sorghum

The couple started processing sweet sorghum flour to make cookies and pandesal and producing other products including vinegar, syrup and, recently, sweet sorghum juice. They also started joining several product exhibits and trade fairs including the DA-BAR’s 2009 National Agriculture and Fisheries Technology Forum and Product Exhibition, an annual affair held at the SM Megamall. It was here that Dr. Nicomedes P. Eleazar, director of BAR saw how BAPAMIN packaged their products.

“That was the opening since Dr. Eleazar knew he could be of help. He knew that the only way our products could compete globally was to have better packaging. So we submitted a project proposal to BAR for funding titled, ‘Sweet Sorghum Processing and Marketing Towards Commercialization in Ilocos Norte’, and luckily it was approved and funded under the Japan Official Development Assistance’s (ODA) – KR2 Program Grant Assistance for Underprivileged Farmers,” recalled Engr. Arcangel.

Specifically, the project aims to: 1) improve the packaging of BAPAMIN’s sweet sorghum products; 2) adopt processing and packaging technologies developed by research institutions such as MMSU, PAC, ISU, and DOST; 3) standardize the processing technologies and specifications of sweet sorghum products; and 4) explore and establish local markets for sweet sorghum products by participating in trade fairs and exhibits.

“The project started in January 2010 and, from then on, we have joined several trade exhibits and have given seminars about the importance of sweet sorghum. We also made available sweet sorghum planting materials and access to the market for the farmers and the producers,” said Engr. Arcangel.

Currently, BAPAMIN products include food items, flour and feed processed from the sweet sorghum grains, and vinegar and syrup processed from the stalks’ juice. Most of the sweet sorghum-based food products are processed in its warehouse in Batac, the bulk of which is vinegar. But unlike traditional vinegar processing, BAPAMIN has developed a faster way of processing the juice into vinegar with an acetator technology that also assures that the product can pass rigid quality control with technical assistance from the DOST and MMSU. The sweet sorghum vinegar that Engr. Arcangel produces is sold at a price competitive with other sugarcane-based vinegar.

BAPAMIN also sells sweet sorghum seeds for planting purposes. According to Engr. Arcangel, the standardization of these products is important because it will soon be adopted nationally. “Luckily, the market potential is now turning into reality and is coming into us and this also gives confidence to the farmers that they have a solid marketing group that will buy their produce,” he added.

The future of the sweet sorghum industry

“With the emergence of markets that are interested in the sweet sorghum products, we can now envision ourselves as going into massive promotion of the planting of sweet sorghum around Ilocos or even other areas,” revealed Engr. Arcangel.

From the initial 20-hectare plantation, an additional 10-hectare from farmer-cooperators, the sweet-sorghum plantation is slowly growing. “Our own goal is to have at least 100 hectares of sweet sorghum for this year. At the national level, the goal is to have an alternative source of biofuel for energy production and sweet sorghum is a very good alternative for fuel and it helps the environment. The ethanol production industry remains the big picture that we would like to look into. It is a viable industry for the nation and will generate jobs and opportunities in the provinces,” he said.

Opportunities continue to pour in as more big companies become interested in buying their products. “Now that we have several groups together planting sweet sorghum, we are assured of good volumes to start with particularly in meeting the demands to supply these big companies,” the happy engineer announced.

“Different organizations and radio programs as well have been inviting us to talk about the sweet sorghum products and, little by little, it’s now getting known widely and I am happy and confident that, with the increasing popularity of sweet sorghum in the Philippines, it will soon come out as a high value crop,” he concluded.

Source: A sweet business enterprise from sweet sorghum: The BAPAMIN experience.